As a lover of good audio, you want a speaker stand that not only has a beautiful design, but is also just perfect in terms of quality. Our speaker stands are made in the Netherlands, so we have a good overview of the entire process. We like to take you through that process, so you know exactly what you are buying when you choose a speaker stand from us.

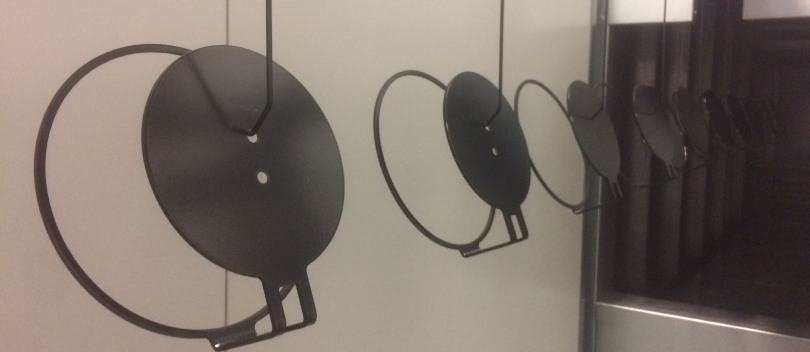

The speaker bracket: from speaker to design

If there is a new speaker on the market or a speaker for which there is no standard yet, we want to make a speaker stand for it. This starts with making a design. The speaker is taken as the starting point for a first sketch. Here, we determine the dimensions and where cut-outs should be made for cables, buttons and LED lights. This careful process ensures that each bracket fits perfectly with the speaker it is designed for, making it functional and beautiful in design.

From the sketch, we create a prototype via a technical drawing. Does it meet the requirements? Then the speaker bracket goes into production. This ensures a seamless transition from concept to reality, where every detail is perfected to meet our high standards.

Universal tube and base

Whereas the speaker bracket differs for each speaker type, we have chosen a universal design for the tube and base. This means that regardless of the specific speaker, our stands provide a solid base.

The tube

We have the tubes made at an external company that we have worked with from the beginning and are very satisfied with. We always make sure we have plenty of our own stock, so we always have enough in stock for an order and are not dependent on delivery times. Meanwhile, we have two varieties to choose from when buying a speaker stand, namely an 80 cm tube and a 100 cm tube. This variety ensures that you can choose the perfect height to suit your space and listening preferences.

The base

The feet are made in Drenthe, Hoogeveen to be precise. This starts with large steel plates that are cut into slabs, from which the shapes of the foot are ground. The feet then proceed to the powder coater, where they go through a production line specially made for us. Here, the feet are rinsed, sprayed, dried, cooled and packed, so they are ready for immediate shipment.

First, the new floor stands

Because we are independent of parties from abroad, we can switch very quickly within the production process. The entire process, from idea to production, takes about 3 to 4 weeks. This does not mean that you have to wait 3 to 4 weeks for your speaker stand. We have a large stock of our existing speaker stands and ship them within 24 hours after ordering. Is there a new speaker on the market? Chances are we will be the first to find a suitable stand!

Insight into the entire process

A speaker stand should be of quality, so that it can do justice to your speaker and its sound. To ensure this quality, we are constantly closely involved in the entire production process of our speaker stands. Not only do we create the design for new speaker brackets ourselves, but we also ensure that the parts are taken from step to step. For this, we have our weekly rounds. This involvement ensures that every product that leaves our warehouse meets our expectations in terms of quality and design.

Ordering a speaker stand

Simply order your speaker stand online and we will start working for you immediately. Within 24 hours, the parts for your speaker stand will be collected and shipped. Our process is optimised to ensure speed and efficiency, without compromising on the quality you can expect from us.